Breadcrumbs

- You are here:

-

Home

-

Forums

-

DIscussions

-

Tech Help

-

General

- A Tale of Two Carbs

A Tale of Two Carbs

- Chris Carlisle

- Topic Author

06 Oct 2016 13:22 #1

by Chris Carlisle

Replied by Chris Carlisle on topic A Tale of Two Carbs

Carb is on the engine now and she runs beautifully. It even feels like there's more torque although the static rpm max is still the same (2200) so I'm sure it's in my head. Also, weather is cooling down and performance is improving as a result.

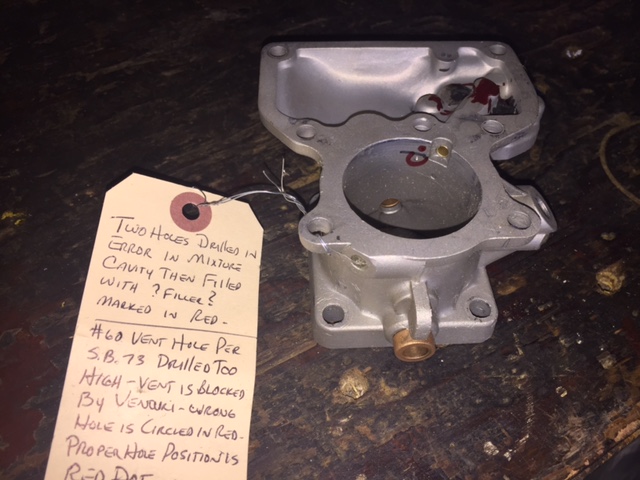

Included is a pic of what Unitech did. This is the upper half of the carb casting turned upside down. You can see that Bob circled in red the hole that was drilled in the incorrect location and then placed a red dot where it should have been drilled to fulfill the requirements of SB 73. Not only was it drilled in the wrong place but at the wrong angle and the result is that the mixture is too rich in the lower rpm ranges below about 1300 or so. He attached a tag explaining all this as you can see. This part had to be junked and he supplied a replacement for a very reasonable price I thought.

He also fixed the mismatched needle valve/seat so there's no more fuel leakage from over filled float bowl. With the new upper casting, the mixture control that most people say doesn't do anything below about 5000 feet altitude now works on the ground at my 1500 msl airport. It won't shut the engine down but it sure makes a difference when the mixture knob is pulled out and it is very precisely adjustable with the longer arm on it.

So, even though the whole affair was pretty spendy, as I mentioned, the confidence and peace of mind are worth it.

Chris

Included is a pic of what Unitech did. This is the upper half of the carb casting turned upside down. You can see that Bob circled in red the hole that was drilled in the incorrect location and then placed a red dot where it should have been drilled to fulfill the requirements of SB 73. Not only was it drilled in the wrong place but at the wrong angle and the result is that the mixture is too rich in the lower rpm ranges below about 1300 or so. He attached a tag explaining all this as you can see. This part had to be junked and he supplied a replacement for a very reasonable price I thought.

He also fixed the mismatched needle valve/seat so there's no more fuel leakage from over filled float bowl. With the new upper casting, the mixture control that most people say doesn't do anything below about 5000 feet altitude now works on the ground at my 1500 msl airport. It won't shut the engine down but it sure makes a difference when the mixture knob is pulled out and it is very precisely adjustable with the longer arm on it.

So, even though the whole affair was pretty spendy, as I mentioned, the confidence and peace of mind are worth it.

Chris

Please Log in or Create an account to join the conversation.

- Chris Carlisle

- Topic Author

23 Sep 2016 16:21 - 23 Sep 2016 16:22 #2

by Chris Carlisle

A Tale of Two Carbs was created by Chris Carlisle

Oops. I somehow managed to submit this originally in the "Suggestions" forum so here it is where I originally meant for it to be posted. Trouble is, I can't get the pretty picture of the carburetor to come over with the text so if you want to see that, check out the posting under same heading in "Suggestion Box".

Man, this airplane ownership comes with a lot of heart and headache. I am still working on making my 415C airworthy and capable of carrying my grandchildren without reservation. The whole story of how it was mis-represented when I bought it and my journey to airworthiness is too long for this venue. Save to say, beware even the most honest appearing guys who are sure that their 'coupe is the best bargain on the planet.

However, I thought the carburetor issue was worth bringing up in this forum. It might save some folks a little trouble and makes for good hangar talk.

My C-85 engine came with a guarantee that the carb was up to date and recently (within last 3 years) overhauled and certified. However, I noticed she didn't run very well at lower rpm's, confronted the seller with this and got him to agree to send the carb back to the most recent overhauler in the upper midwest. It came back very nicely assembled but when installed, didn't solve the problem. The idle mixture needle had to be screwed completely in to the carb body for the engine to run anywhere close to smoothly and even then, it was obviously too rich.

I then contacted Bob Kachergius (the Stromberg Specialist) at Unitech Air Management. At first, he came off as kind of an over-enthusiastic salesman and I have to admit I was a little nervous about taking his word for it, but in the end, sent him the carb.

I got it back yesterday and what a beautiful work of engineering art. As it turns out, the prior overhauler messed things up so badly that the upper half of the carb casting had to be discarded. He not only sent this back but included a detailed explanation of how it was messed up with red 'Sharpie' markings on it to detail where the errors were made. The documentation that came with it is extensive and thorough including a well constructed logbook entry to paste in documenting what was done. More specifically, and as he'd predicted before even receiving the carb, the famous SB 73 had not been done properly so that it was running too rich in the idle circuit. Apparently, this is a common problem and has to be addressed very carefully to fulfill the letter of the SB.

I haven't had time to install it on the plane yet but suspect that things will be better once I do. In any case, beware the Stromberg carburetor that has not been properly overhauled and certified. I don't see a lot of accidents on the NTSB site attributable to engine failures related to this but was so impressed with my experience that I thought I'd share. He sent all new hardware for installation along with and included new gaskets. The workmanship is beautiful and even if it doesn't solve my low rpm roughness problem, I know now that the carburetor is up to the highest standard and safe to fly.

Will update after installation.

Chris

415C, ser # 508

Sioux Falls, SD

Man, this airplane ownership comes with a lot of heart and headache. I am still working on making my 415C airworthy and capable of carrying my grandchildren without reservation. The whole story of how it was mis-represented when I bought it and my journey to airworthiness is too long for this venue. Save to say, beware even the most honest appearing guys who are sure that their 'coupe is the best bargain on the planet.

However, I thought the carburetor issue was worth bringing up in this forum. It might save some folks a little trouble and makes for good hangar talk.

My C-85 engine came with a guarantee that the carb was up to date and recently (within last 3 years) overhauled and certified. However, I noticed she didn't run very well at lower rpm's, confronted the seller with this and got him to agree to send the carb back to the most recent overhauler in the upper midwest. It came back very nicely assembled but when installed, didn't solve the problem. The idle mixture needle had to be screwed completely in to the carb body for the engine to run anywhere close to smoothly and even then, it was obviously too rich.

I then contacted Bob Kachergius (the Stromberg Specialist) at Unitech Air Management. At first, he came off as kind of an over-enthusiastic salesman and I have to admit I was a little nervous about taking his word for it, but in the end, sent him the carb.

I got it back yesterday and what a beautiful work of engineering art. As it turns out, the prior overhauler messed things up so badly that the upper half of the carb casting had to be discarded. He not only sent this back but included a detailed explanation of how it was messed up with red 'Sharpie' markings on it to detail where the errors were made. The documentation that came with it is extensive and thorough including a well constructed logbook entry to paste in documenting what was done. More specifically, and as he'd predicted before even receiving the carb, the famous SB 73 had not been done properly so that it was running too rich in the idle circuit. Apparently, this is a common problem and has to be addressed very carefully to fulfill the letter of the SB.

I haven't had time to install it on the plane yet but suspect that things will be better once I do. In any case, beware the Stromberg carburetor that has not been properly overhauled and certified. I don't see a lot of accidents on the NTSB site attributable to engine failures related to this but was so impressed with my experience that I thought I'd share. He sent all new hardware for installation along with and included new gaskets. The workmanship is beautiful and even if it doesn't solve my low rpm roughness problem, I know now that the carburetor is up to the highest standard and safe to fly.

Will update after installation.

Chris

415C, ser # 508

Sioux Falls, SD

Last edit: 23 Sep 2016 16:22 by Chris Carlisle.

Please Log in or Create an account to join the conversation.

Time to create page: 0.044 seconds